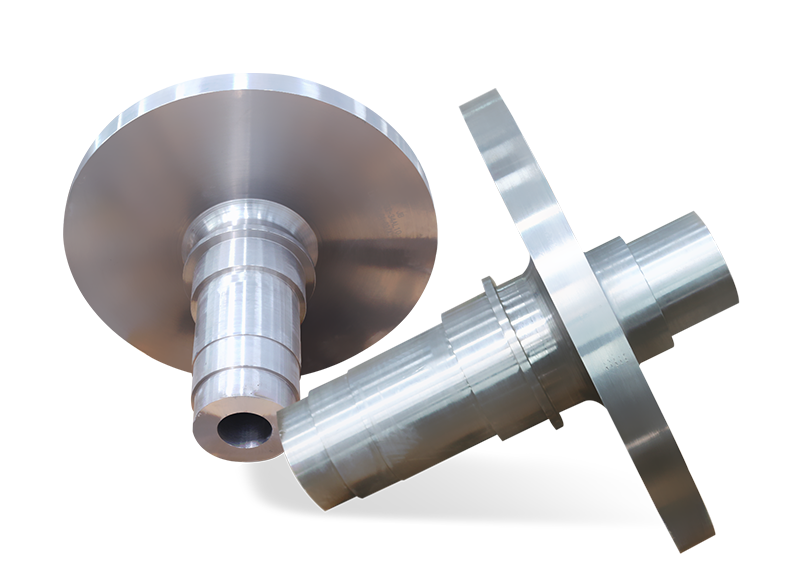

Centrifuge Parts

Application:

Kinglink has developed a series of centrifugal-casting stainless steel parts used for industrial centrifuges. An industrial centrifuge is a mechanical device that uses centrifugal force to separate substances of different densities. Central to their operation is a rotating drum or bowl, powered by a motor, which finds application across diverse industries such as pharmaceuticals, chemical processing, food and beverage, and oil and gas.

The drum or bowl is the main component of the centrifuge, and it is where the separation takes place. The drum or bowl is typically made of stainless steel. Kinglink stands out as a global supplier, providing a range of semi-finished drums and other components through stainless steel centrifugal casting, meeting the demanding needs of industries worldwide.

Materials

Kinglink is able to supply each customer or market with the required materials.

Capacity:

Kinglink has an annual capacity of 8,000 tons of various stainless steel casting parts, the sizes are up to:

Outer diameter of 1,500 mm

Length(or height) of 5,000 mm

Unit weight of 5,000 K